EX850 Excavator

Hitachi EX850 Excavator Cylinder failures contained by Mag-Shield®

Solution

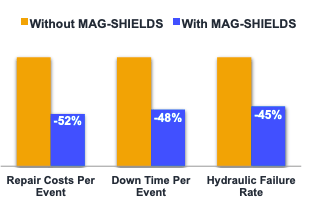

By encompassing the current reservoir suction screen with Mag-Shield® filters from MagShield® – NEXT GENERATION BEST PRACTICE for fluid contamination control, we effectively captured and retained contaminants, ensuring they are kept away from the pump suction inlets. This proactive measure not only safeguards against contamination buildup on the reservoir screen but also mitigates the detrimental effects of cavitation.

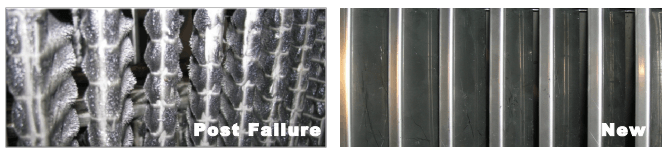

Attached, is a photo of one of the Mag-Shield® after a cylinder failure on an EX850 excavator. Mag-Shield® captured material that would have spread throughout the machine. NACG saved a lot of money as we did not have to disassemble the hydraulic system for major cleaning. The actual savings estimate is greater than $70,000 and could be over $100,000. These estimates are compared to previous cylinder failures we have experienced with EX850s that did not have Mag-Shield®, which resulted in contaminated hydraulic systems.

Paul O’Riordan

Sales Manager

: +1 780 984 8647

: paul.oriordan@magshield.com

Dean Cryer

Business Development Manager

: +1 780 966 8647

: dean.cryer@magshield.com

Neil Cropper – Australia

General Manager

: +61 409 269 873

: neil.cropper@magshield.com

Murray Laidlaw

Sales Manager

: +61 437 072 396

: murray.laidlaw@magshield.com