EQUIPMENT:

Komatsu 830E

Client: Diamond Mine In Canada

Product: Mag-Shield® and Mag-Probe®

Komatsu 830E Haul Trucks Monitored by Mag-Probe®

Solution

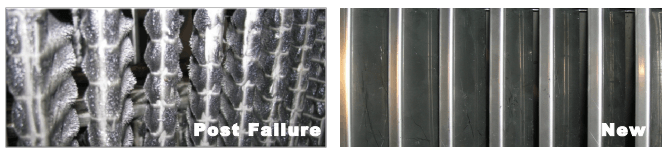

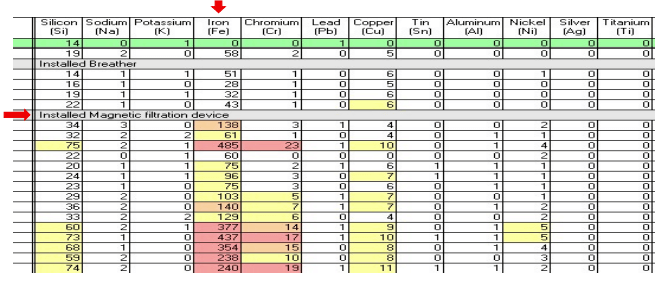

The operators equipped a pair of trucks with Mag-Shield® and Mag-Probe® kits as part of a trial. The intention was to provide oil filtration to capture as much ferrous contamination as possible and provide a method of visually monitoring iron contamination within the hubs and wheel motors. Mag-Shield® were installed in the wheel motor sumps, and Mag-Probe® were installed both in the wheel motor filler caps and the front wheel hubs.

Paul O’Riordan

Sales Manager

: +1 780 984 8647

: paul.oriordan@magshield.com

Dean Cryer

Business Development Manager

: +1 780 966 8647

: dean.cryer@magshield.com

Neil Cropper – Australia

General Manager

: +61 409 269 873

: neil.cropper@magshield.com

Murray Laidlaw

Sales Manager

: +61 437 072 396

: murray.laidlaw@magshield.com