Cat 797 trucks

Mag-Shield® capture debris from component failures, saving hydraulic systems from massive damage in a large fleet of CAT 797 haul trucks

Solution

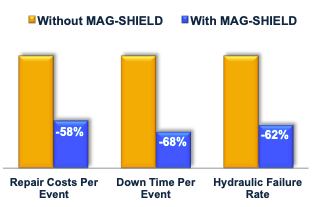

At the customer’s request, We developed Mag-Shield® magnetic filters for the hydraulic system. The customer installed Mag-Shield® on one of several problematic trucks that was experiencing numerous repeat failures. The results were immediate: the trial truck did not experience any additional failures which lead to the customer immediately adopting Mag-Shield® across the entire fleet. Since installing Mag-Shield®, there have been no system-wide failures or follow-on failures in the machines, and repair costs and down time have been drastically reduced.

The customer has designated MagShield® – NEXT GENERATION BEST PRACTICE for fluid contamination control as an “official reliability improvement” for its mine sites.

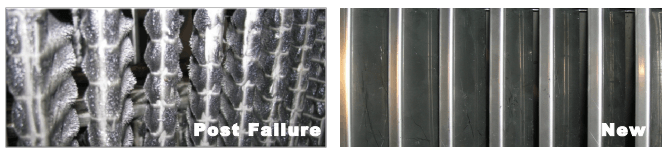

“We have attached a few pictures to show Mag-Shield®‘s effectiveness at capturing metal contamination that standard factory hydraulic filters were unable to capture or contain. Mag-Shield® are performing to the level we had expected.”

Paul O’Riordan

Sales Manager

: +1 780 984 8647

: paul.oriordan@magshield.com

Dean Cryer

Business Development Manager

: +1 780 966 8647

: dean.cryer@magshield.com

Neil Cropper – Australia

General Manager

: +61 409 269 873

: neil.cropper@magshield.com

Murray Laidlaw

Sales Manager

: +61 437 072 396

: murray.laidlaw@magshield.com