EQUIPMENT:

CAT 797F haul truck

Client: Mining Company In Australia

Product: Mag-Shield®

Mag-Shield® improve oil sample results in a CAT 797F haul truck

Solution

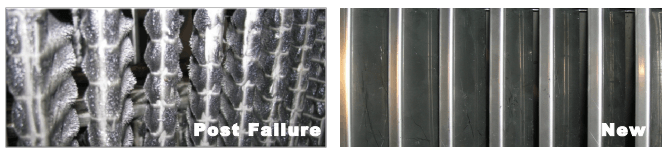

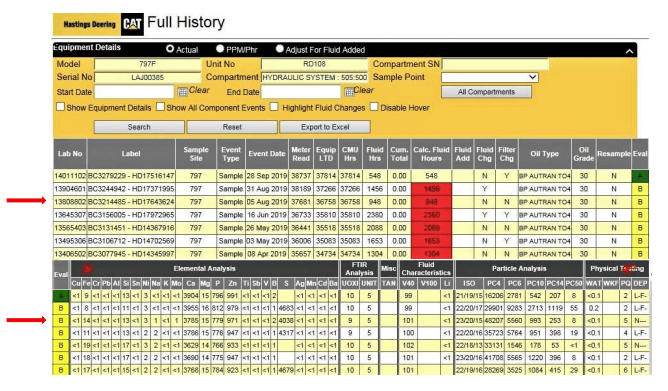

We provided a Mag-Shield® filter. The operator installed it during repairs performed on August 5th (see chart). The Mag-Shield® system is designed to remove ferrous particles from the fluid flow. This prevents the abrasive particles from continuing to circulate within the system and cause additional damage, such as scoring machined surfaces in pumps. The system was flushed according to manufacturer-recommended procedures and the unit was returned to service.

Paul O’Riordan

Sales Manager

: +1 780 984 8647

: paul.oriordan@magshield.com

Dean Cryer

Business Development Manager

: +1 780 966 8647

: dean.cryer@magshield.com

Neil Cropper – Australia

General Manager

: +61 409 269 873

: neil.cropper@magshield.com

Murray Laidlaw

Sales Manager

: +61 437 072 396

: murray.laidlaw@magshield.com