THE MAGSHIELD DIFFERENCE

- Up to 80% reduction in equipment downtime post component failure.

- 18+% component life improvement.

- Up to 10% mechanical availability through reduction of secondary failures post-component repair.

- 4000-hour Oil life Improvement.

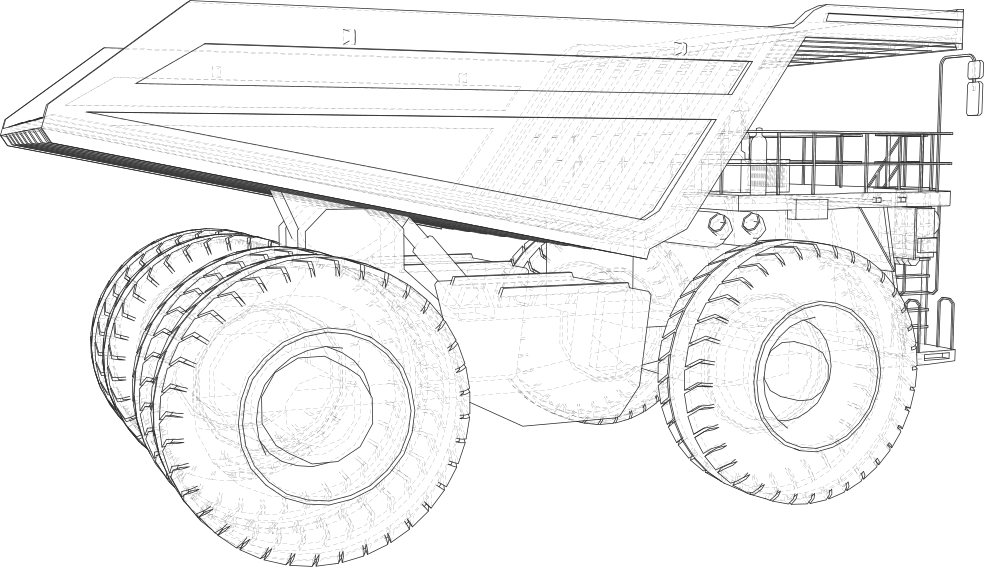

Rear Differential

Rear Wheel Group

Front Wheel Group

Hydraulic Reservoir

INNOVATIVE PRODUCTS

ASSET PROTECTION

Why let iron contamination affect your system life cycle? Improve existing fluid filtration, uptime, and reliability in your hydraulic and fluid systems with intuitive yet effective asset protection. MagShield magnetic filters capture ferrous contamination for a rapid return on investment, including in systems with high flow and high fluid volume.

Mag-Shield ® is ideal for applications with higher fluid volumes and those where the fluid reservoir is easily accessible. This ultra-high-capacity product captures ferrous material on each pass without restricting or altering the flow. It supports existing filtration, minimises failures, and controls iron contamination as it happens.

Learn more >

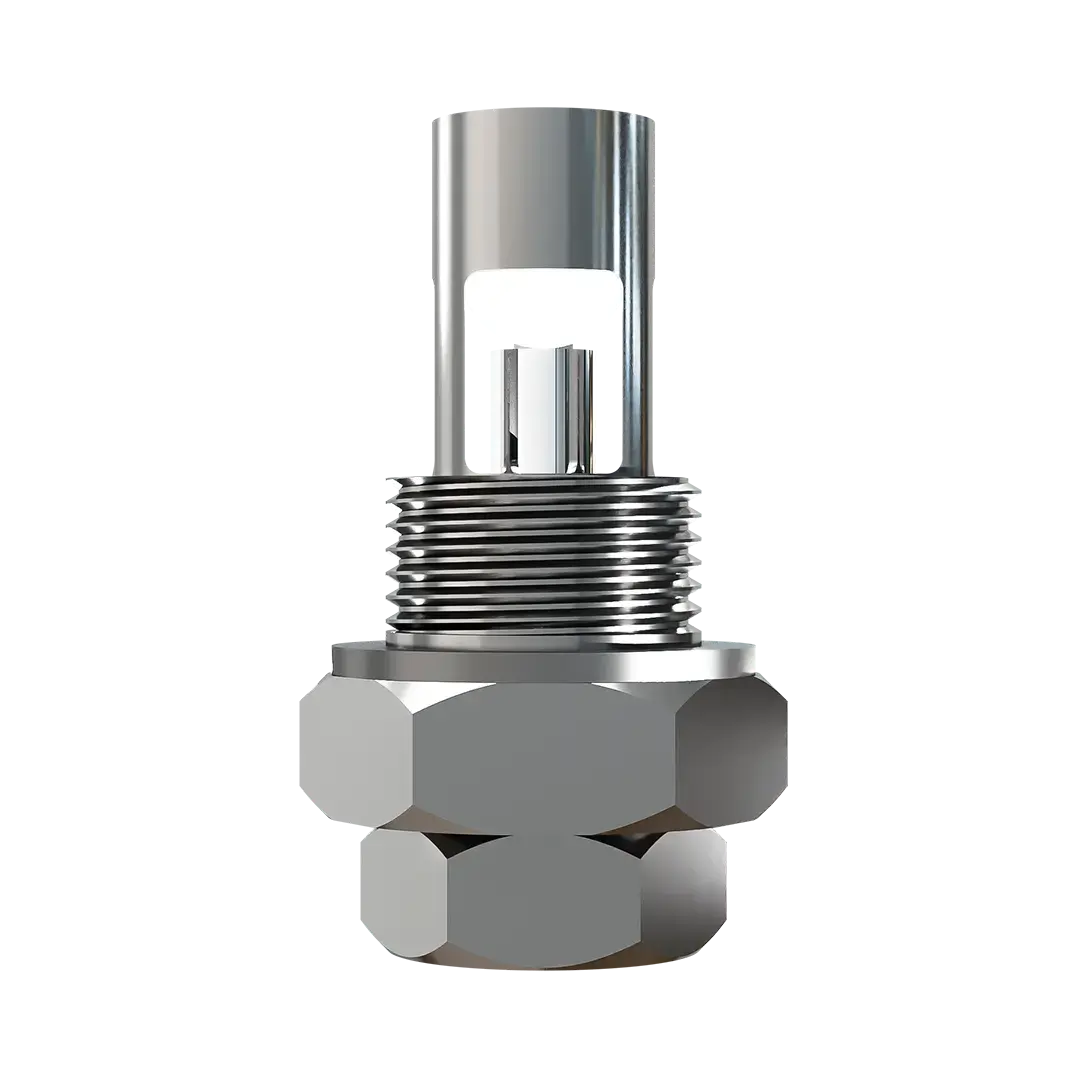

Mag-Shield® X is ideal for high-flow applications and systems where the reservoir may be less accessible. A high-capacity magnetic element is situated within a traditional filter housing for easy installation and serviceability, complementing existing filters and constantly cleaning ferrous contaminants from the fluid system.

Learn more >

DIAGNOSTICS

Ferrous contamination can be invisible – until it leads to huge problems. Mag-Probe® is an essential condition monitoring tool for every heavy machinery and equipment operator, as you can instantly identify and assess ferrous fluid contamination in your system. This makes it far easier to minimise and prevent the high costs of iron contamination.

Mag-Probe®, Our magnetic diagnostic tool is also invaluable in making safer, better-informed decisions around asset protection.

Learn more >

Testimonials

Dean Cryer

Business Development Manager

: +1 780 966 8647

: dean.cryer@magshield.com

Jorge Infanta

Sales Account Manager

: +1 780 909 8232

: jorge.infanta@magshield.com

Stacy Dukart

Sales Account Manager

: +1 780 984 8647

: stacy.dukart@magshield.com

Neil Cropper – Australia

General Manager

: +61 409 269 873

: neil.cropper@magshield.com

Simon Lewis – Australia

Business Development Manager

: +61 455 298 814

: simon.lewis@magshield.com

Barry Erasmus – Australia

Business Development Manager

: +61 472 567 040

: barry.erasmus@magshield.com