Hitachi EX8000 Excavator

Mag-Shield® stop Repeat Failures and reduce fluid contamination confidence in contamination alarm

system restored.

Solution

In response to the challenges, the operator reached out to the Mag-Shield® team.

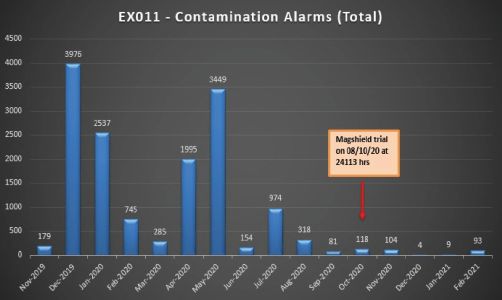

A Mag-Shield® magnetic filter solution was installed into the main hydraulic tank of the excavator. This innovative solution is designed to capture iron contamination that is generated during normal operation, as well as any residual contamination following a failure.

This prevents the contamination from recirculating within the system, thereby reducing the frequency of false alarms from the contamination detection system. Furthermore, it allows for accurate oil analysis and diagnostic trending to continue, typically at a lower baseline reference. This case study explores the effectiveness of the MagShield solution in addressing the operational challenges faced by the EX8000 excavator.

The state-of-the-art Mag-Shield® filtration system from MagShield® – NEXT GENERATION BEST PRACTICE for fluid contamination control, has been seamlessly installed in the primary hydraulic tank of the Hitachi EX8000 excavator.

Dean Cryer

Business Development Manager

: +1 780 966 8647

: dean.cryer@magshield.com

Jorge Infanta

Sales Account Manager

: +1 780 909 8232

: jorge.infanta@magshield.com

Stacy Dukart

Sales Account Manager

: +1 780 984 8647

: stacy.dukart@magshield.com

Neil Cropper – Australia

General Manager

: +61 409 269 873

: neil.cropper@magshield.com

Murray Laidlaw

Sales Manager

: +61 437 072 396

: murray.laidlaw@magshield.com