Cat 777 trucks

Mag-Shield® prevent expensive brake damage in fleet of CAT 777 haul trucks

Solution

The company chose MagShield® – NEXT GENERATION BEST PRACTICE for fluid contamination control. Since installing Mag-Shield® in the hydraulic systems of the fleet, brake damage has been prevented and follow-on failures have been eliminated. Post repair, residual contamination is captured by the Mag-Shield® in the hydraulic tank and prevented from circulating back into the hydraulic system.

Customer quote:

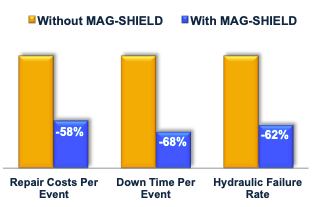

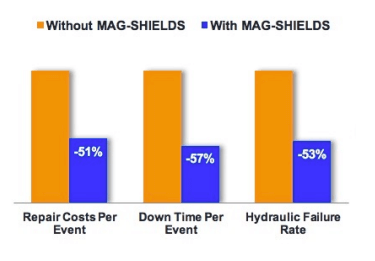

“Since installing Mag-Shield® over 6 years ago, hydraulic failure costs have dropped dramatically. Our biggest savings are realized from not having to replace brakes and cylinders on a 777 truck following a hydraulic failure. On a 777D, $96K is saved on brake components alone. Down time for repairs has been cut in half or less and the trucks do not experience follow-on failures. Larger trucks realize increased savings. Have a look at the attached pictures.”

Dean Cryer

Business Development Manager

: +1 780 966 8647

: dean.cryer@magshield.com

Jorge Infanta

Sales Account Manager

: +1 780 909 8232

: jorge.infanta@magshield.com

Stacy Dukart

Sales Account Manager

: +1 780 984 8647

: stacy.dukart@magshield.com

Neil Cropper – Australia

General Manager

: +61 409 269 873

: neil.cropper@magshield.com

Murray Laidlaw

Sales Manager

: +61 437 072 396

: murray.laidlaw@magshield.com